The history

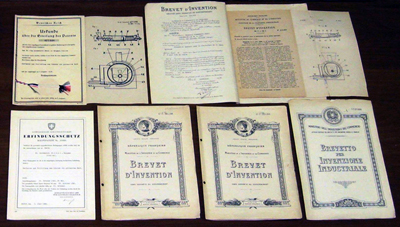

INGG. MEANI name, active in Italy since 1930, in the Lime, Cement and Gypsum sectors, becomes notorious in Europe in 1936, thanks to the patents of Simplex Lime Hydrator.

Dr. Ing. Alessandro Meani,

the founder (1904-1965)

Some Meani's European Patents of lime hydration

Apparatus and Process

The first registration of DR. ING. ALESSANDRO MEANI Company, N. 21244 at Chamber of Commerce of Bergamo, has been made in 1934.

The original lime hydration Apparatus 1936

The present

The Family group INGG. MEANI continues, in his historical location, the original activity to supply Technical Assistance, Consulting and Eingineering based on well established priofessional experience of the Engineers (Mario, Ennio, Franco and Matteo) under the service brand INGG MEANI ®, cooperating with external mechanical shops.

Professional activity aiming to the continuous technological improvement in the process of prodution of Lime and Gypsum. Operating and cooperating with external shops, also of the Customer, new plants are built up and important improvement are achieved at very competitive costs.

Lime Hydrator with Dryvapor Filter

Some significant dates and achievements of INGG. MEANI® are as follows:

Gypsum Kilns with Dryvapor Filter

1934 Vertical layers, limestone + coal, Kilns

1936 Patent of SIMPLEX Hydrator in most european countries

1945 New vertical layers Kilns and Multiple, fuel Lime Kilns with peripheral chambers for different combustibles

1946 Patent of Self-ventilated Refiner Mill

1955 New Italian Patent of process and apparatus, for dry hydrated lime production with process water self pre–heating

1967 First installation in Italy of a rotary discontinuous kiln, indirect heating, for plaster with high Beta-hemihydrate content

1970 First plants for hydrated stabilized lime and immediate bagging of the final product, without the seasoning silos

1975 Automatic charging and distribution, limestone + cooke, Systems for large upright cooke - fired vertical lime kilns

Electronically controlled Wind Separators

1983 Patent of highly efficient FPA all steel Gypsum kiln, with efficient sleeves filters for dedusting fumes and vapors with easy maintenance

1990 Direct dry de-dusting of wet fumes and vapors of Gypsum kilns by means of "DRYVAPOR Gypsum" System. Pressure control of the combustion process, cooking and hydration process.

1993 "DRYVAPOR Lime" System, with the most evident feature was of direct positioning the sleeves filter on top of lime Hydrators (This original System is now universally imitated but never overcome in terms of efficiency).

Vertical lime Kiln with Dryvapor Filter

2003 New Lime Hydrators and electronically controlled wind Separator presentation. Improvement of INGG. MEANI® Bags Filters for Lime and Gypsum Kilns wet fumes and vapors with specific features in order to increase the efficiency and reduce maintenance and ecology charges.

2010 Improvement of vertical lime kilns with more efficient combustion systems for all type of fuel and output

2013 Presentation on the domestic and International Market of the most rational and competitive system for Gypsum baking.

TODAY Research and continuous study about the optimisation of production lines and in particular of de-dusting Systems for hydrated lime and gypsum plants, on specific cases.